Our history

Experience you can trust

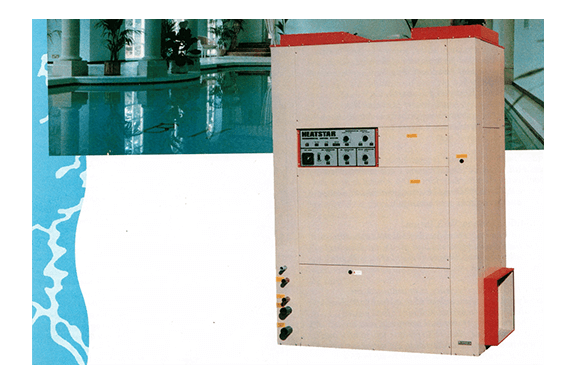

Heatstar have long been established as the market leader in the design and manufacture of modern, highly energy efficient, environmental control systems for swimming pools, with an enviable reputation for quality.

For over 40 years Heatstar have been guiding their clients towards responsible energy solutions for swimming pools, setting the benchmark in an environmentally conscious industry.

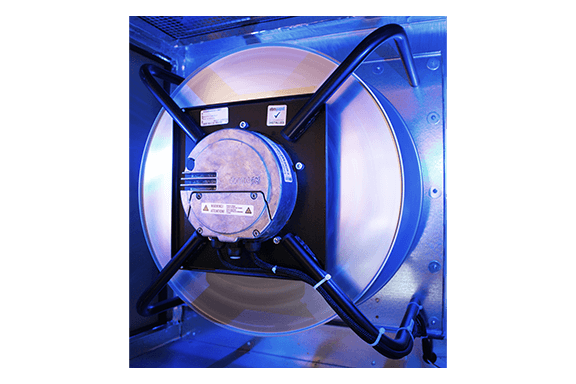

The heat pump as a heating method for swimming pools was developed by Tony Andrews, the founder of Heatstar and the father of current Heatstar Director Jackie Scott. His involvement was in response to increased energy awareness resulting from the 1973 oil crisis. His expertise came from his previous job as Chief Design Engineer at a large air conditioning manufacturing company. There, Tony was latterly responsible for creating fresh air and ground source heat pump design concepts for general heating applications .

Tony Andrews possessed the vision to appreciate the potential future market for energy saving products that could literally “produce heat out of thin air” and he also possessed the engineering expertise to design and produce a successful product.

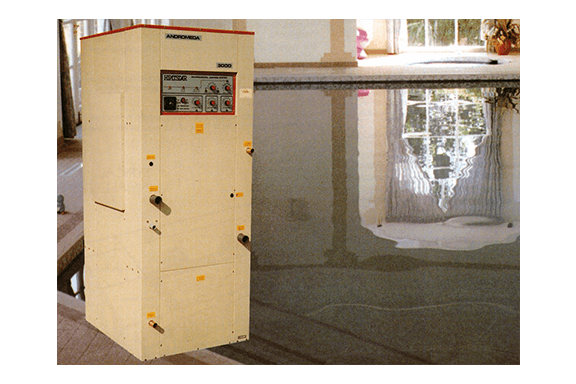

In 1980 Tony Andrews launched his own business venture creating the first fresh air source heat pumps for dedicated application on swimming pools – The Heatstar “brand” was born.